ADSS (All-Dielectric Self-Supporting) fiber cable is a crucial component in modern telecommunications infrastructure. It offers numerous advantages in terms of installation, maintenance, and performance. This article will delve into the structure of ADSS fiber cable, the accessories required for its installation, and the scenarios in which it is preferred.

Structure of ADSS Fiber Cable

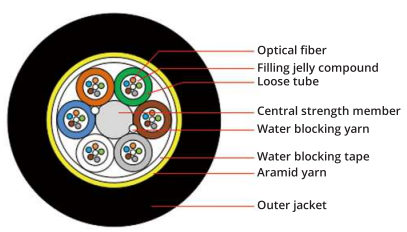

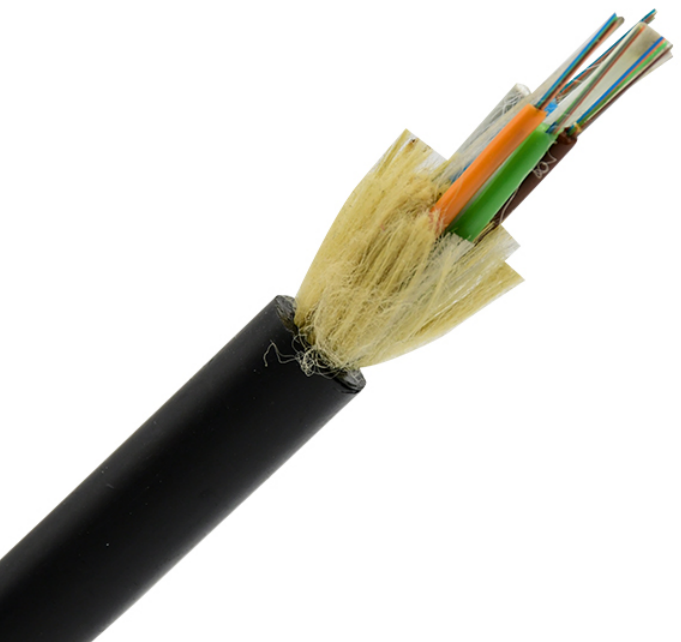

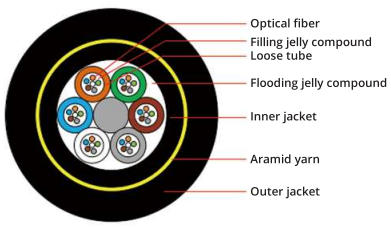

ADSS fiber cable consists of several layers designed to provide strength, protection, and insulation without the need for a metallic support or messenger wire. The typical structure includes,

Optical Fibers: These are the core components of the cable, carrying the data signals over long distances. They are typically made of glass or plastic and are arranged in a tight buffer to protect against environmental factors.

Strength Member: The strength member provides mechanical support to the cable. It is usually made of aramid yarns (such as Kevlar) or fiberglass rods, ensuring the cable can withstand tension and bending during installation and operation.

Water-Blocking Material: ADSS cables are designed to be water-resistant. Water-blocking materials, such as water-swellable tapes or gels, are applied to prevent water ingress, which could degrade the optical fibers.

Dielectric Jacket: Unlike traditional cables that use metallic materials for strength, ADSS cables feature a dielectric jacket made of materials like polyethylene (PE) or polyvinyl chloride (PVC). This jacket provides insulation and protection against environmental factors like UV radiation and extreme temperatures.

Single Protector ADSS

|  |

Double Protector ADSS

|  |

Installation Accessories

Several accessories are essential for the installation of ADSS fiber cable

Suspension Hardware: This includes brackets, grips, and suspension clamps used to attach the cable to poles, towers, or other support structures.

Preformed Line Products (PLP): PLP components, such as dead-ends and guy grips, provide additional support and tension relief at termination points and bends.

Cable Pulling Equipment: Tools like cable pullers, tensioners, and rollers are necessary for safely pulling the cable along its route without causing damage.

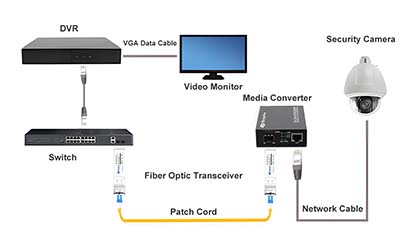

Connectors and Splicing Equipment: Connectors and splicing equipment are required for terminating and joining optical fibers, ensuring seamless connectivity throughout the network.

When to Choose ADSS Fiber Cable and Why?

ADSS fiber cable is preferred in several scenarios due to its unique characteristics,

Aerial Installations: ADSS cables are specifically designed for aerial installations, where traditional metallic support structures may be impractical or unavailable. They can be installed on existing power lines or telecommunication poles without the need for additional support hardware.

Long-Span Applications: ADSS cables excel in long-span applications, such as across rivers, highways, or rugged terrain, where traditional cables would require costly support structures or underground installation.

High-Voltage Environments: The dielectric nature of ADSS cables makes them ideal for high-voltage environments, such as near power lines or substations, where metallic cables pose a risk of electrical interference or corrosion.

Low Maintenance: Compared to traditional metallic cables, ADSS cables require minimal maintenance due to their robust design and resistance to environmental factors like moisture and corrosion.

ADSS fiber cable offers a versatile and reliable solution for aerial telecommunications infrastructure, with its unique structure, installation accessories, and suitability for various applications making it a preferred choice in many scenarios.

Sopto Technology is a professional manufacturer and supplier of optical fiber cables. We specialize in the production of ADSS fiber cables with various core counts, as well as various types of indoor and outdoor fiber cables.

Tags : ADSS fiber cable, outdoor fiber cable, Aerial Fiber Cable

— END —