As the application of optical fiber in network communication becomes more and more widespread, various optical fiber devices have emerged at the same time. Visual fault locator is one of the commonly used optical fiber inspection tools for troubleshooting network faults. Visual Fault Locator is also called light pen, pen-type red light source, visible light detection pen, fiber fault detector, fiber fault locator, etc. It is driven by a constant current source to emit a stable red light, and it is connected to the optical interface to enter the fiber to quickly detect the light. Connectivity and locate fiber failure points.

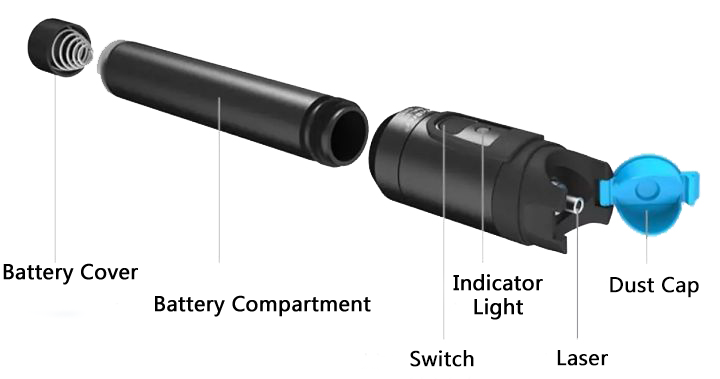

Visual Fault Locator is divided into 5Km, 10Km, 15Km, 20Km, 25Km, 30Km, 35Km, 40Km, etc. according to its shortest detection distance. The structure of Visual Fault Locator is mainly divided into battery compartment, laser, indicator light, switch, dust cap and Battery cover, etc.

What are the uses of Visual Fault Locator?

After laying fiber optic cables in underground, overhead, pipelines, etc., sometimes due to various factors such as lightning strikes, rodents, gunshots (overhead), pipeline collapse, etc., the fiber optic cables are damaged and naturally broken. After a fault occurs, we often cannot find the point of the obstacle intuitively. If blindly searching will cost a lot of manpower and material resources, Visual Fault Locator can solve this problem well. Visual Fault Locator can be driven by a constant current source to output a red laser visible to the human eye. The penetrating power is extremely strong, and the light leaking from the fault point is still clearly visible through the 3mm PVC layer, and the fault point can be accurately found.

When wiring the ODF distribution frame in the computer room, use the Visual Fault Locator to make the optical fiber connector introduce the red light into the optical fiber, which can check whether the optical fiber is broken and ensure that there is no problem with splicing; it can also be used as a core wire comparison for multi-core optical cables; Optical fiber failure points and high-loss sections caused by microbending that cannot be found by OTDR.

How to use Visual Fault Locator?

1. Install the battery and check if the Visual Fault Locator is in good condition

Open the battery cover, put the matching battery into the battery compartment (pay attention to the positive and negative poles of the battery). Turn on the dust cap and control switch of the Visual Fault Locator, and observe whether the Visual Fault Locator has a red light. A red light means the Visual Fault Locator is installed. Correct, you can use it (note that it is strictly forbidden to look directly into the red light).

2. Choose the appropriate connector according to the type of fiber patch cord

Visual Fault Locator has a simple and quick interface, which is suitable for all 2.5mm fiber optic connectors. Choose the corresponding connector according to the interface type of the fiber optic jumper. For example, for the LC fiber jumper, choose the LC connector to install on the Visual Fault Locator interface, and then install the fiber Insert the jumper into the connector of the Visual Fault Locator (clean the interface with a cleaning tool before inserting the optical fiber jumper).

3. Open the Visual Fault Locator working mode to detect fiber jumpers

Push up the Visual Fault Locator to emit continuous light, check whether the fiber jumper is connected and intact. If there is no red light leakage in the fiber jumper, it means the fiber jumper is in good condition. If there is a red light leak somewhere in the fiber jumper If it is not, push it down to switch to the blinking mode of Visual Fault Locator, and quickly find the fault point of the fiber jumper through the blinking light.

Precautions for using Visual Fault Locator

1. Laser is harmful to eyes, avoid exposure to human or animal eyes

2. If the brightness of the laser beam is severely reduced, please charge or replace the battery.

3. High temperature will affect the service life of Visual Fault Locator, so Visual Fault Locator should avoid high temperature working environment as much as possible and store it in a cool and dry place.

4. Wear a dust cap in time when not using Visual Fault Locator to prevent dust and other pollution

5. Please take out the battery when not in use, and put it out of the reach of children

Tags : Visual Fault Locator,fttx,fiber,fiber patch cord

— END —