Pre-connectorized MDU (Multi-Dwelling Unit) solutions are a highly efficient approach to deploying fiber in apartment buildings and other multi-unit residences, often seen in Fiber to the Home (FTTH) implementations.

Pre-connectorized solutions involve fiber components that come pre-assembled with connectors, which reduces the need for field splicing. Components such as fiber cables, splitter modules, and wall-mounted distribution boxes are delivered ready-to-connect, minimizing installation time and improving overall project efficiency.

Key Components of a Pre-Connectorized MDU Solution

Pre-terminated Fiber Cables : These cables are pre-fitted with connectors and cut to standard or customized lengths, allowing installers to quickly plug them into the distribution boxes.

Optical Splitter Modules : Splitters divide the optical signal to serve multiple users, with various splitting ratios (e.g., 1:4, 1:8, 1:16) depending on the required connections. In MDU setups, pre-connectorized splitter modules simplify installation and reduce handling of delicate fiber strands.

Distribution Boxes : Wall-mounted boxes are placed at key points (e.g., floors or entry points) in the building to provide accessible, organized connections for individual units.

Connectorized Drop Cables: These short cables connect from the distribution boxes to each residence. With connectors on both ends, drop cables are simply plugged in, completing the fiber link from the central equipment to each dwelling.

Advantages of Pre-Connectorized MDU Solutions

Reduced Installation Time : No splicing or specialized tools are required, and connections are made by simply plugging in the cables, reducing installation time significantly.

Lower Labor Costs : Skilled labor is minimized as fewer splices are needed, leading to reduced project costs.

Easier Troubleshooting and Maintenance : Pre-connectorized cables can be easily unplugged for testing, making fault-finding faster and less complex.

Scalability : Adding new connections is straightforward—installers can plug in additional cables as new residents or units are added to the network.

Application Scenarios

Pre-connectorized solutions are ideal for MDU environments such as apartment complexes, high-rise buildings, and gated communities, where installing and managing large numbers of connections quickly is essential. This solution is also beneficial in retrofitting older buildings where space for cabling infrastructure is limited.

Implementation Process

Site Survey and Planning: Engineers assess the MDU layout and plan fiber routes, drop locations, and distribution box placements.

Pre-Connectorized Component Installation: Pre-terminated cables and connectors are installed from the main terminal to each distribution box.

Connecting Each Unit: The final step involves plugging the connectorized drop cables into each unit's optical network terminal (ONT), completing the end-to-end connection.

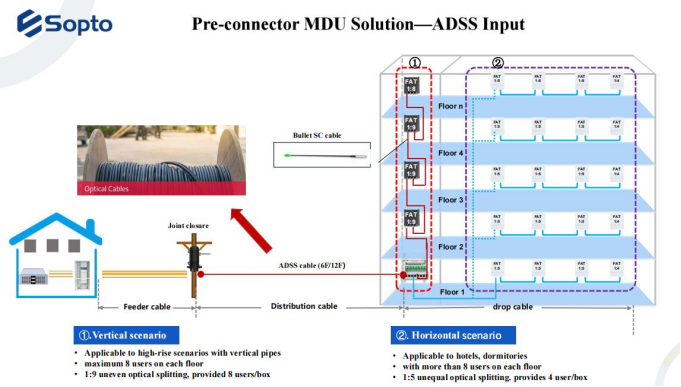

Sopto Pre-connectorized MDU (Multi-Dwelling Unit) solutions two deployment approaches: ADSS input and Hub Box input. Each approach differs in wiring methods and equipment connections, and the choice often depends on building structure, requirements, and budget. Below is a detailed introduction to each solution

1. ADSS Input Solution

ADSS (All-Dielectric Self-Supporting Cable) is a type of fiber optic cable that is non-metallic and self-supporting, typically used for outdoor cabling. Its dielectric design makes it suitable for long-distance wiring from the central office to buildings without interference from high-voltage power lines.

ADSS Input Solution

Characteristics

Non-metallic Design : ADSS cables contain no metal components, providing excellent insulation for use in environments with high-voltage lines or strong electromagnetic interference.

High Tensile Strength : ADSS cables can be suspended without additional support structures (e.g., steel wires), simplifying installation on building exteriors or between structures.

Weather Resistant : These cables have high resistance to wind and tension, making them suitable for long-term outdoor deployment in harsh environments.

Deployment Process

Cabling from Central Office to MDU Building : ADSS cables are suspended from the central office to the building’s exterior or entry point.

Cable Termination Distribution Box : At the building entrance, a pre-connectorized distribution box is installed to connect ADSS cables to indoor splitters or distribution units via pre-terminated connectors.

Connecting Distribution Units : The signal is distributed to each floor or apartment through the distribution unit, completing the in-building connection.

Advantages

Suitable for Long-distance Outdoor Cabling : ADSS is ideal for outdoor, long-distance deployment due to its high tensile strength and insulation.

Simplified Installation : No additional support or cable tray structures are required.

Low Maintenance : Without metal components, ADSS is free from electromagnetic interference, ensuring stable operation around power lines.

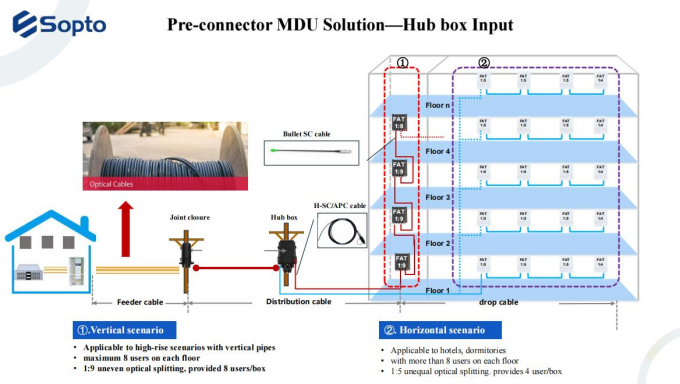

2. Hub Box Input Solution

The Hub Box input solution is a centralized fiber cabling approach within the building. The Hub Box is typically installed in a central location, from which fiber jumpers connect each apartment to the main fiber backbone.

Hub Box Input Solution

Characteristics

Centralized Management : Hub Boxes are installed in hallways, equipment rooms, or other central areas, making management and maintenance convenient.

Flexible Expansion : Additional fiber connections can be easily added to the Hub Box as needed, allowing for future network growth.

Space-saving Wiring : The centralized Hub Box design enables flexible in-building wiring and reduces the need for extensive cabling on each floor.

Deployment Process

Installing the Hub Box : The Hub Box is set up in a hallway, elevator shaft, or basement.

Backbone Cabling : Pre-terminated cables connect the central office to the Hub Box and then to the main distribution fiber.

Distributing to Each Unit : From the Hub Box, pre-terminated drop cables connect each unit to an Optical Network Terminal (ONT), distributing the signal to each residence.

Advantages

Centralized Management : Centralized Hub Box deployment simplifies maintenance and troubleshooting.

Lower Installation Cost : Compared to floor-by-floor cabling, centralized management reduces cable usage, saving costs.

Suitable for High-density Units : The Hub Box input solution can support a large number of fiber connections, making it ideal for high-density residential buildings.

Comparison of ADSS and Hub Box Solutions

Feature | ADSS Input Solution | Hub Box Input Solution |

Application Scenario | Suitable for outdoor, long-distance cabling | Suitable for centralized indoor cabling |

Wiring Method | Overhead installation from the central office to the building exterior or entry point | Centralized wiring with backbone cable to each floor |

Maintenance | More dispersed, requires outdoor maintenance | Centralized, facilitating maintenance and trouble shooting |

Installation Cost | Slightly higher installation cost but saves on support structures | Lower cost, ideal for high-density residential use |

Each of these solutions offers unique advantages and can be selected based on the building structure, wiring environment, and project budget, making them effective choices for pre-connectorized MDU solutions. Sopto Technology is committed to providing the best solutions for our partners. If you would like to get more details, please contact us. Email: [email protected] and whatsapp: https://wa.me/+8618688759008/

Tags : Pre-connectorized MDU solutions, FTTH Solutions, ADSS fiber cable , Hub Box

— END —